[Global Network Technology Comprehensive Report] On June 30, Alibaba announced that the digital agricultural collection and processing center (hereinafter referred to as the origin warehouse) in Guangxi and Yunnan has been fully operational.

Within this year, Alibaba Digital Agriculture will also build three production warehouses in Sichuan, Shaanxi and Shandong, forming five national agricultural products collection and transportation hubs, and build more than 20 land sales warehouses in several provincial capitals. In the mode of "producing warehouse+selling warehouse", a digital agricultural product circulation network will be initially formed, which can support 1 million tons of fresh agricultural products to be sent to the national table every year.

It is understood that the production warehouses in Guangxi and Yunnan are built near Nanning and Kunming airports, which is convenient for air and land transportation. It is also the largest agricultural product collection and processing place in Guangxi and Yunnan.

The daily delivery capacity of Guangxi warehouse phase I is nearly 300 tons, and that of Yunnan warehouse phase I is about 150 tons. It mainly involves fresh agricultural products, such as wogan, pitaya, passion fruit, pomegranate, mango, pineapple, papaya and purple potato.

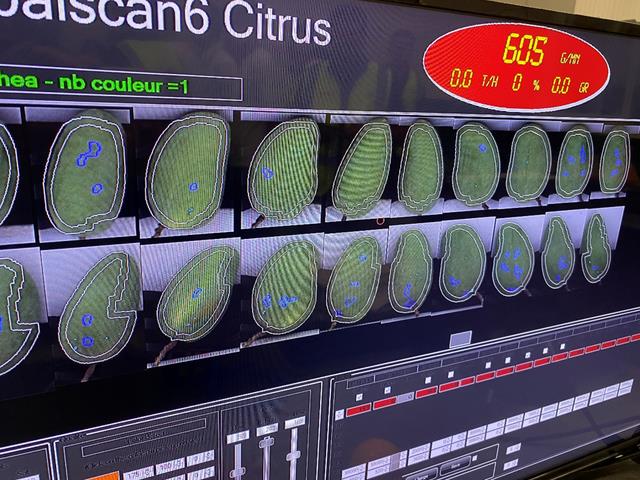

Digitalization is the biggest feature of the two warehouses. According to reports, the digital central control room can keep abreast of the data and warehousing of agricultural products in the two provinces; The fruits are sent to a four-channel sorting equipment. Just like CT, the photoelectric sorter can measure the sweetness and sourness of each fruit, the smoothness of the fruit surface, and whether there are mildew spots, orange peels and scratches. As for the fruit diameter, it can be accurate to millimeters and the weight can be accurate to 0.5 grams.

Efficiency is the key factor of producing warehouse. In the dual-channel sorting line of Kunming origin warehouse, skilled workers can sort out up to 450 kilograms of fruits a day, while the sorting line can "classify" 7 tons of fruits in one hour. The efficiency is 124 times that of the former.

The transformation from agricultural products to commodities involves many processes such as sorting, quality control, packing, billing, etc., and the digital and automatic warehouse of origin only takes two minutes to complete these processes.

High efficiency will not make farmers lose their jobs. In Guangxi and Yunnan, nearly 600 jobs were provided in the early days to help farmers become industrial workers.

The warehouse of origin is more like a fruit fresh-keeping box. In Nanning warehouse, 40,000 cubic meters of cold storage is kept at 0-4℃. It is estimated that the loss rate of fresh agricultural products can be reduced from 20%-30% to 10%, and this part of the profits can be "returned" to farmers.

Hou Yi, president of Box Horse Business Group and president of Alibaba Digital Agriculture Division, said that Ali has opened a "fruit shuttle bus" and a "flower shuttle bus" in Yunnan, which can ensure that fruits are shipped out of Yunnan every day and transported to Beijing, Shanghai and other cities in the cold chain.

In addition to building five major agricultural product producing warehouses nationwide this year, Alibaba Digital Agriculture also plans to build more than 20 land selling warehouses nationwide. At present, more than half of the land selling warehouses have been put into operation.

Reporting/feedback

关于作者