Correspondent Tang Tang Our reporter Zhang Wei

When people get sick, they often have to hang water to take medicine. However, after the drug enters the human body, it is not smooth sailing to reach the designated position, stay for a longer time, be better absorbed, and avoid being accidentally injured by friendly forces.

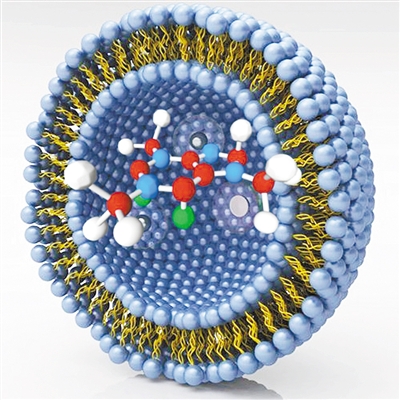

In recent 20 years, more and more new nano-pharmaceutical preparations have flooded into the market, and nano-liposomes with the name of "small steamed buns" in the carrier have emerged as the times require. This kind of vesicle with nanometer particle size formed by lipid bilayer can wrap drugs with great toxic and side effects, poor stability and rapid degradation. By fusing with the cell membrane, the carried drugs are concentrated in the focus, so as to achieve targeted administration, and at the same time, the curative effect can be improved, the toxicity can be reduced, and the stability can be enhanced.

Recently, Professor Gu Ning of Southeast University led a team to break the technical barriers abroad, overcome the key technologies of nano-lipid materials, built the first domestic and largest production line of lipid nanoparticles in the world, and won the first prize of scientific and technological progress in Jiangsu Province.

Then, how does this nano-scale "little one" take on the heavy responsibility of "packaging" and "transporting" through-train service? What other unknown uses do nanoliposomes have besides their great potential in drug carriers?

Known as the secret weapon of "rejuvenation"

The formation of liposomes is due to the self-assembly properties of a substance called phospholipids. Phospholipid is an amphiphilic substance, one end is hydrophilic and the other is lipophilic. Due to the particularity of its molecular configuration, phospholipid will spontaneously assemble into a bimolecular membrane structure in water, and part of it will be wrapped inside, which is usually called "vesicle".

The earliest liposomes were naturally formed in water. After scientists discovered its special skills, they tried to synthesize phospholipid compounds by artificial methods in order to achieve the purpose of mass production. The diameter of liposomes is usually tens of nanometers to tens of millimeters, and "nano-liposomes" are liposomes with nanometer particle size.

The membrane structure of lipid nanomaterials is very close to the cell membrane, which provides convenience for drug delivery and absorption. Therefore, liposomes can wrap the effective components and introduce them into cells, so that the effective components can easily enter cells.

In many common drugs, liposomes are responsible. Such as antineoplastic drugs, drugs targeting reticuloendothelial system, protein and nucleic acid drugs, antibacterial drugs, anti-inflammatory hormone drugs, etc. Moreover, the drug with liposome as the carrier "skin is not delicate" can be administered in any way, including intravenous injection, subcutaneous and intramuscular injection, oral administration, pulmonary administration and skin administration.

"The size of liposomes is related to the route of administration and drug release rate, but nano-sized liposomes have obvious advantages as drug carriers." Professor Gu Ning told reporters that daunorubicin liposomes, for example, have a particle size of 60-mdash; 120 nm, because of its small particle size, it is not easily recognized by phagocytes of reticuloendothelial system after entering the blood circulation, so it can stay in the blood circulation for a long time. At the same time, the pharmaceutical preparation has no obvious cardiotoxicity.

In recent years, more and more nanoliposome drugs have flooded into the international market and become the fastest-growing high-end pharmaceutical preparation in the world. Nanoliposomes not only play an important role in the pharmaceutical industry, but also act as a professional "courier" in cosmetics. It can keep the activity of cosmetics well, so that growth factors and other ingredients can enter the stratum corneum faster and more completely, thus enhancing the cell repair ability. Therefore, liposome encapsulation is known as the secret weapon of "rejuvenation".

Oil-loving and hydrophilic "amphiphilicity" increases the difficulty of mass production

In recent years, in the international pharmaceutical field, dexterous and multifunctional nanoliposomes have almost become "online celebrity".

At present, a total of 29 nanoliposome drugs have been approved for marketing in the world. In addition, there are 87 nanoliposome drugs in clinical research stage and 132 nanoliposome drugs in preclinical research stage. Among them, there are 13 nanoliposome drugs approved for marketing by the US Food and Drug Administration (FDA).

In sharp contrast, only three nanoliposome drugs in China have been approved for production, namely paclitaxel liposome for injection, doxorubicin hydrochloride liposome and amphotericin B liposome for injection.

But 10 years ago, the related drugs and cosmetics in China were blank, and the people in China could not touch them at all, because the key technologies of lipid nanomaterials were in the hands of foreigners.

The international market share of nanoliposome drugs is increasing year by year, but the industrialization development in this field in China has been slow. "The reason is that the lipid nanomaterials needed by nanoliposome drugs are completely imported, and their prices far exceed the raw materials themselves; Second, the quality, purity and stability of domestic liposome pharmaceutical preparations need to be improved; Third, the assembly technology of lipid nano-materials and the preparation technology of lipid nano-drugs have high requirements and great difficulties. " Professor Gu Ning told reporters.

In 1970s, when liposomes were first used as drug carriers, they were once ignored because of their extremely unstable structure and low drug encapsulation efficiency. With the in-depth study of liposomes, the existing problems have been solved initially. In the early 1990s, economical and efficient anti-fungal and anti-cancer drug liposomes were put into the market, which greatly promoted the research and development of liposomes.

Lipid nano-materials have unique hydrophilic and lipophilic "amphipathy", which makes it possible to add lipophilic and hydrophilic drugs and active ingredients to the same drug at the same time.

However, researchers have also found that the amphiphilic nature of lipid nanomaterials is a double-edged sword, which not only provides convenience for drug loading, but also increases the difficulty of mass production. Therefore, the preparation process of lipid nano-materials is complex, which makes it difficult to remove impurities, and it is difficult to purify intermediates and products, so it is difficult to achieve mass production.

It is also a treasure to use "the wind blows on both sides"

The raw materials for preparing nanoliposomes are not complicated, but if you can’t master the doorway, you can’t make qualified nanoliposomes.

Well-made liposomes have a phospholipid bimolecular shell, which is very similar to the structure of cell membrane, and they are very small, and their diameters are basically below 150 nanometers, which is helpful for the penetration of active substances.

To realize the localization of lipid nanomaterials, the synthesis process is particularly important. Therefore, Professor Gu Ning’s team put forward an innovative new process for synthesis and purification of lipid nanomaterials. Through self-made separation filler and independent separation and purification technology, they realized the industrialization of high-purity lipid nano-medicinal carrier materials.

Lipid nano-materials are hydrophilic at one end and lipophilic at the other, which seems to be "the wind blows on both sides", so how to use them well is also very particular. After repeated experiments, researchers finally found a "trick up my sleeve". "We creatively put oil-soluble drugs on the oleophilic outer layer and water-soluble drugs on the hydrophilic inner layer, giving full play to the role of drugs, and truly fostering strengths and avoiding weaknesses." Professor Gu Ning said.

According to Professor Gu Ning, they developed a new process for the synthesis and purification of lipid nanomaterials, which used a "one-pot" reaction to prepare key intermediates, and the yield was doubled. At the same time, the liposome coordination technology broke through the key bottleneck of the assembly of glycyrrhizic acid drug phospholipid complex. Diammonium glycyrrhizinate was complexed with phosphatidylcholine, a lipid material, to form a lipid complex, which greatly improved the lipophilicity of glycyrrhizic acid and made it easier to cross the multiple membrane structures of the digestive tract and enter the blood circulation, effectively solving the problem of low oral bioavailability of glycyrrhizic acid.

After the success of the project, the price of domestic lipid nano-materials dropped significantly, which significantly reduced the overall cost of liposome drugs. In addition, lipid nanoparticles technology has been widely used in domestic first-line cosmetics companies, and it has played a great role in preparing cosmetics with whitening, anti-aging and wrinkle removal functions.

关于作者